Case Study: Reducing Mold Changeover Time — From Improvement Activities at Shiga Plant

- SANKO GOSEI

- Dec 8, 2025

- 3 min read

Injection molding factories inevitably face the critical task of mold changeovers. The time required for these changeovers is a major factor directly impacting productivity, and reducing it often becomes a company-wide improvement initiative.

This article introduces specific measures implemented at Sanko Gosei's Shiga Factory to reduce mold changeover times, along with the resulting effects.

1. Background and Objectives

The Shiga Plant had previously focused improvement activities on reducing changeover time for its 650-tonne Machine No. 8. Previous enhancements included organising the pre-setup area, retrofitting cranes with low-speed stop functionality, introducing sealed couplers, and preparing for H.R.C. (Hot Runner Control). These measures collectively achieved a monthly time reduction of 329 minutes for this single machine.

Building on these results, the new objective is to horizontally deploy these measures to Press No. 1 (2000 tonnes) and other molding machines. The ultimate goal is to achieve the factory target of ‘limiting changeover time to under 15 minutes for all molding machines’.

2. Action Plan for Reducing Changeover Time

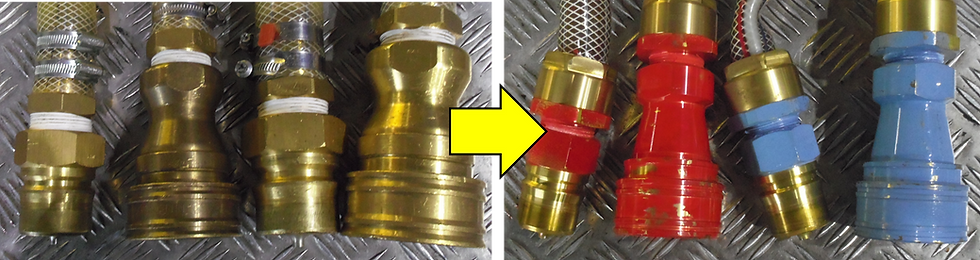

Action 1: Implementing Sealing Couplers on All Molding Machines

The first initiative undertaken was the introduction of sealed couplers across all molding machines. Implemented according to a phased schedule tailored to each machine type, this aimed to reduce connection times and alleviate operator workload. Particularly for small and medium-sized machines, where conventional couplers were too large and cumbersome to use, smaller couplers were adopted and specification revisions were carried out.

Action 2: Improvement of the pre-setup area

To reduce changeover time, the key is to minimise operations performed after halting the molding machine. To achieve this, a new “pre-setup area” has been established. This allows preparatory work to be carried out in advance, alongside ancillary equipment such as the mold master and H.R. controller.

Action 3: Standardisation and Improvement through Changeover Oversight

To standardise changeover procedures and review workflows, each team took turns monthly to publicly demonstrate changeover operations. These demonstrations were observed by a multi-disciplinary team including the Plant Manager, Production Section Manager, Mold Maintenance, and Equipment Maintenance personnel, who then discussed points for reflection and improvement proposals.

During these actual observations, instances were achieved where the operation time fell below 15 minutes, facilitating the effective sharing of standardised work practices.

3. New Issues Identified on Site and Their Improvement Measures

Particularly for machines under 450 tonnes, the existing couplers were too large in size, making connection within the moulding machine difficult. To address this, a change to smaller hoses and couplers was implemented.

Issue 2: Residual pressure in hydraulic couplers causing connection difficulties

The issue of residual pressure in the coupler affecting subsequent mould changes was addressed by installing a new pressure relief plug.

Issue 3: Complicated signal line connections

Multiple signal lines were connected individually, resulting in prolonged work times and errors. To address this, we consolidated the signal lines using Harting's one-touch couplers, enabling connection completion in a single operation.

Issue 4: Chuck replacement cannot be performed by one person

On large machines, chucks larger than the products themselves were used, making single-operator work difficult with conventional equipment. Switching to Star Seiki's tool changer enabled simultaneous locking, signalling, and air connection with a single button press. Furthermore, introducing a dedicated chuck stand improved mobility.

Issue 5: Poor positioning accuracy of the gate cutter

The anchor-type system suffered positional deviation due to floor instability, so it was changed to a one-touch system combining an air cylinder and tool changer, enabling highly reproducible positioning.

Challenge 6: Crane movement efficiency

When changing molds during changeovers, using a single crane resulted in time being taken up by lifting, moving, and setting the mold. By transitioning to a three-person operation, the third person compensated for setup losses, thereby accelerating changeover speeds.

4. Verification of Effects and Outcomes

As a result of these activities, the average time required for a changeover was reduced by approximately 4.1 minutes, from 21.7 minutes to 17.6 minutes. With an average of 597 changeovers per month, this translates to an annual saving of 489.6 hours, estimated at approximately ¥880,000.

5. Future Outlook

The following policies have been established for further improvement:

Standardisation of changeover procedures and development of standard operating procedures: Ensuring consistent results regardless of operator.

Promotion of single-operator chuck replacement: Transitioning from two-person to one-person operation through adoption of Star Seiki chucks.

Integrated operation of standby gate cutter and chuck: Adopting a set structure to achieve automated exchange.

Achieving a 15-minute changeover time: Continuous improvement targeting a further reduction of 2.6 minutes.

Summary

This case exemplifies how tackling mold changeover time reduction through a multifaceted approach—encompassing “standardisation”, “automation”, and “shifting operator mindset”—yields significant results beyond mere operational efficiency gains. Such a comprehensive perspective will increasingly be required in future mold changeover improvement activities.

Comments