Introduction of a case study for improving clogging of sprue runners in a crusher

- SANKO GOSEI

- Sep 3, 2024

- 2 min read

Clogging problem of sprue runners

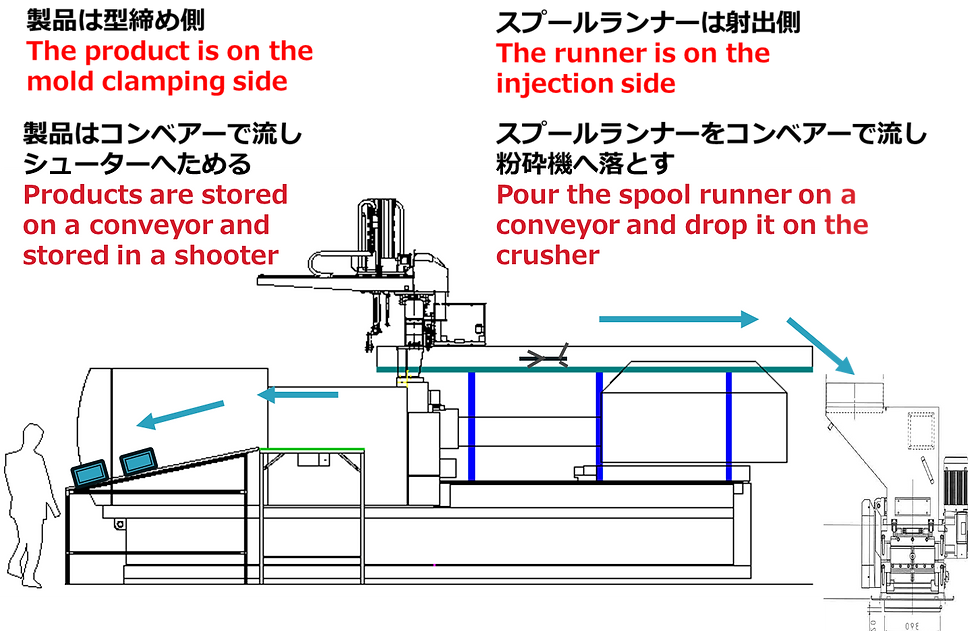

At our mass production plant, runners that are no longer needed after molding are put into a crusher and crushed. This is done not only to reduce the bulk, but also to add recyclability, as the crushed runners can be mixed with resin pellets and injection molded again.

However, the sprue runners ejected from the molding machine have been clogging during transport and in the crusher. This clogging not only reduced production efficiency, but also placed a heavy burden on the stage change operators. There have also been reports of return loss due to clogging and other negative effects such as separate milling processes.

Causes and effects of clogging

The main cause of clogging depends on the size and shape of the sprue runner. Especially long sprue runners and those with specific shapes tend to get caught on conveyors and in crushers during conveying.

This can require operators to manually remove clogging, which reduces work efficiency and can lead to unstable product quality.

Introduction of remedial measures

In response to this problem, we have implemented several remedial measures at our mass production plant.

1. improvement of runner conveyor:

An acrylic plate is attached to the side of the conveyor and a lid is provided to prevent dust and foreign matter from entering the conveyor. In addition, a seam was inserted at the connection of the acrylic plate to prevent the sprue runner from getting caught during conveyance.

2. improvement of the crusher:

For crushers, we introduced Harmo granulators and Watanabe Steel mills and used them according to the shape of the sprue runner. This design made clogging less likely to occur and enabled more efficient crushing. The runner prone to clogging this time will be a 3 hp.

3. Cutting sprue runners: Cutting sprue runners into two pieces with nippers.

When it is difficult to place long sprue runners on the conveyor, they are cut into two pieces using nippers to prevent clogging. For stronger resins, we also tried using heat nippers to cut the sprue runners.

Effects and Results

As a result of implementing these improvement measures, the number of clogged sprue runners was significantly reduced and production efficiency improved. In particular, the introduction of sprue runner cutting has eliminated clogging at a success rate of nearly 100%. In addition, the workload of the step change man has also been reduced, contributing to a reduction in work costs.

Comments