Laser machining for invisibles Structure of instrument panel with passenger airbag.

- SANKO GOSEI

- Jan 20, 2025

- 1 min read

In automotive instrument panels (instrumental panels)

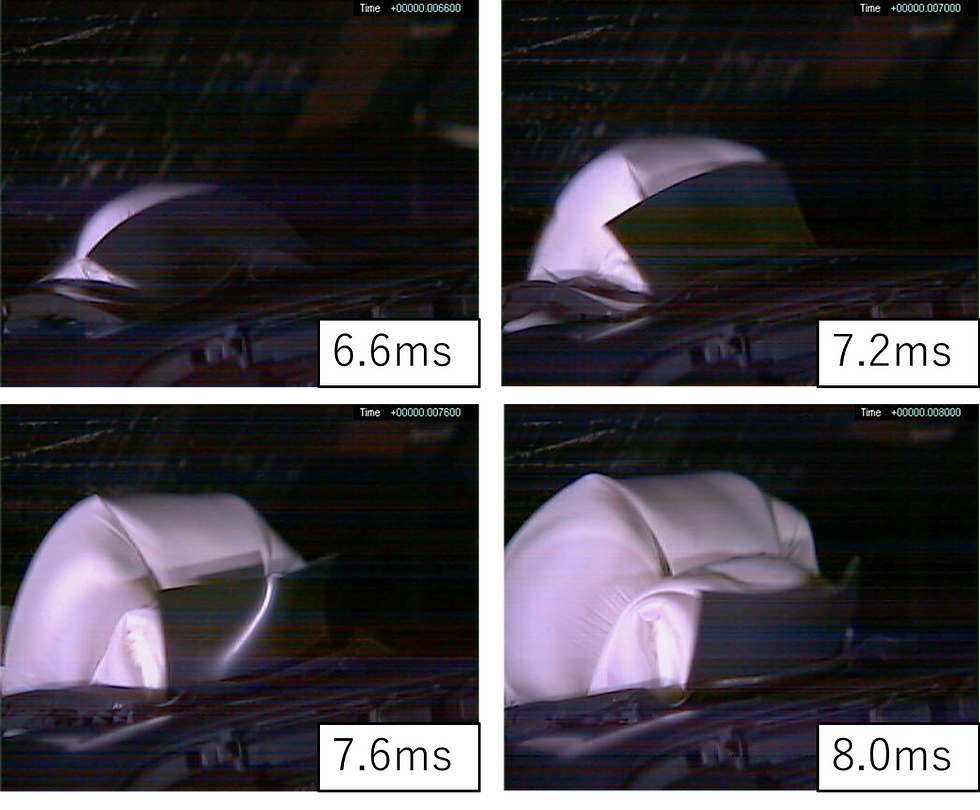

In recent years, the front passenger airbag opening has been located in front of the front passenger seat and the opening tear line has become invisible and inconspicuous.

[Tear line - the groove that bursts when the airbag deploys, indicated by the red frame in the image].

This not only gives an integrated texture on the same surface, but also leads to more freedom in the design of the instrument panel design.

The instrument panel surface serves as the airbag opening, with the opening tail line laser-machined from the back side so that it is not visible from the instrument panel surface, and a retainer injection-moulded from TPO resin is vibration-welded to the back side.

During quality control, it is important to check the laser machining marks and control the number of all holes and the number of NG holes.

Laser processing machines

In vibration welding, it is also important to control weld strength and weld melt allowance.

Vibration welding machine

Our thorough quality control ensures that airbag operation is not affected before delivery.

Comments