Continuous molding with a mold without gas vent...?

- SANKO GOSEI

- Jul 25, 2025

- 3 min read

This article describes the results and discussion of what happens to the molded product when it is continuously molded in an injection mold without a gas vent.

◆What is a gas vent?

A gas vent is a groove for venting out gases in the mold that have no place to escape as the resin fills the mold. Some types are connected to the molded product, while others are located around the cavity periphery.

Without these grooves, the gases in the mold cannot escape and are adiabatically compressed in the mold, which can lead to ignition. This ignited residue adheres to the molded product, resulting in molding defects such as “burning” and “gas burns”.

Even if gas burning does not occur, molding defects such as “shorts” and “short shots”, where the resin does not fill to the end, are also likely to occur.

Click here for a cartoon-style explanation of the phenomena occurring in the mold ➡The causes of short shots are explained! The fierce battle between resin and air

This time, we conducted an experiment to see what results could be achieved when continuous molding is carried out with a mold without gas vent using PA66 (nylon) resin, which has a proven track record in mass production.

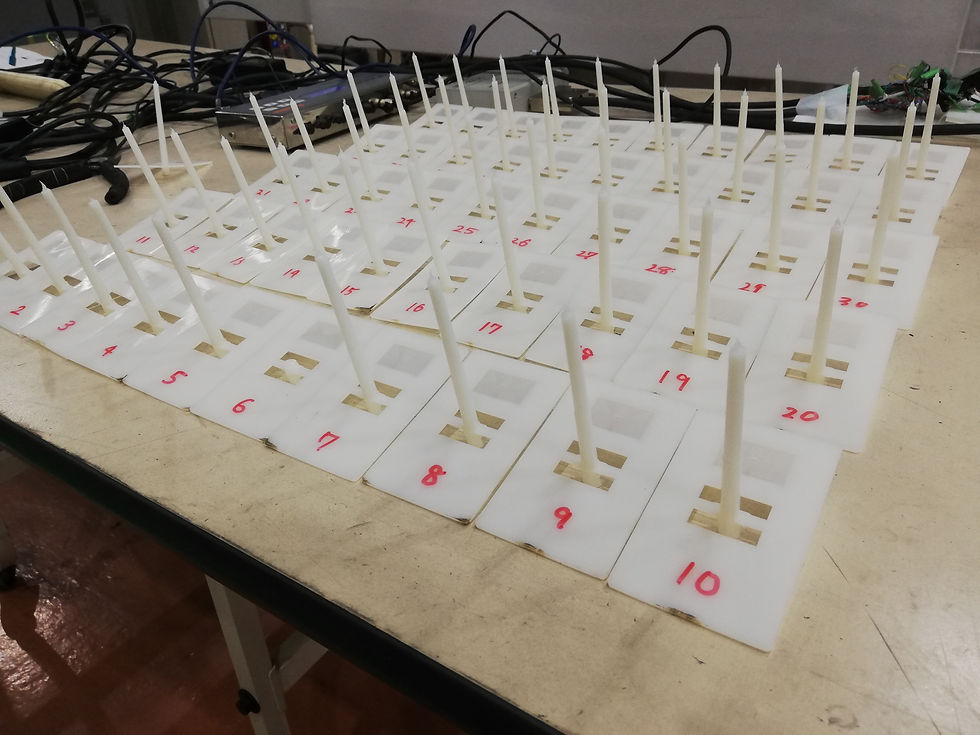

◆Continuous molding experiment using a mold without gas vent

Resin used: PA66 (Toray CM3001-N)

Moulding machine: sodick GL-150

Product shape: Direct gate, flat plate with wall thickness varying from 2 mm to 0.5 mm

Mould specification: No gas vent

Moulding conditions: Set under the conditions under which the molding could be carried out without problems with gas venting.

◆Moulding results

Burning occurs at the final filling point from the 3rd shot after the start of molding.

Burning occurs continuously from the 5th shot. It was found that the occurrence point moved not only at the final filling point but also at each shot

◆Causes of shifting of the location of the burns?

This molded product has a symmetrical shape, so if the resin flows as described above, it should be the same spot every shot, but why are the spots different from shot to shot? The following factors were considered.

Factor 1: Material variation.

Even if the raw material resin is of the same grade, there are subtle differences between production lots. This may have changed the fluidity of the material when melted down. ➡ This is possible with recycled materials, but unlikely to occur with virgin materials.

Factor 2: Moisture absorption of resin

Resins (e.g. nylon) are hygroscopic and absorb moisture from the air. If the material absorbs moisture, gas is more likely to be generated during injection molding, leading to defects such as short shots and gas burns.

➡It is conceivable after a chocolate stop, but why does it occur in continuous molding?

Factor 3: changes in mold temperature

In continuous molding over a long period of time, the temperature inside the mold tends to change over time, making it easier for cooling efficiency and shrinkage balance to be disrupted. ➡Possible?

Factor 4: Temperature changes during injection

Similar to the mold temperature, the temperature control of injection molding machines tries to maintain a constant temperature by switching on and off. Even if the temperature is set at 260°C, if the temperature changes for each shot, the fluidity may also change. ➡Possible?

From these considerations, it was considered that temperature changes during molding were a factor in the shifting position of the final filling point. However, it is difficult to take very realistic measures as it is not possible to measure the temperature of every shot.

Before that, it is clear that measures such as the installation of gas vents are necessary, as the occurrence of burning is a molding defect. It is easy to face new problems such as changes in the final filling point as well as simply the occurrence of burning, which can lead to a labyrinth of countermeasures.

We need to go back to the basics of molding to prevent this from happening.

Comments