Improvement Case Study: Y-rib Shortage Issue and Countermeasures

- SANKO GOSEI

- Dec 19, 2025

- 3 min read

Introduction

As part of our efforts to improve the quality of case housing products, we implemented an improvement initiative focusing on ‘Y-rib short defects’. This case study details how we achieved zero defects by clarifying the defect occurrence mechanism and implementing effective countermeasures, while simultaneously significantly reducing inspection workload and mold maintenance man-hours.

Background and Challenges

The case housing is a complex molded component manufactured by combining various single-axis and dual-axis inserts, with product variations totalling 36 types. Among these, the “Y-rib” – which plays a crucial role in preventing components from detaching from the main body – had been experiencing chronic short shot defects.

This defect was identified during the assembly inspection process. As its occurrence directly leads to functional failure, 100% inspection was conducted at two stages: after molding and after assembly. Consequently, the inspection burden was high, and the risk of defects escaping inspection was not fully mitigated.

Understanding the Defect Situation

Analysis of sorting results from January to March 2015 revealed that “Y-rib short” defects accounted for 88% of all defects, totalling 7,680 instances (out of 8,700 total defects). Representative defect items are shown below.

Defective items | Number of cases | Defect rate |

Y-rib short | 7,680 | 88% |

Void | 600 | 7% |

wrinkle | 420 | 5% |

Based on this, we determined that the shorting of the Y-rib should be addressed as the top priority issue.

Root Cause Analysis

Upon disassembling and inspecting the molded part, it was found that the tip of the Y-rib had shorted, rendering it prone to detachment from the product. Upon thorough investigation, the following facts were established:

The Y-ribs within the mold had a dead-end shape prone to gas accumulation, and the solid mold structure (i.e., difficult to vent) meant gas could not escape during resin filling, causing short defects at the rib tips.

The narrow grooves were difficult to clean, making the mold susceptible to dirt build-up, and even after cleaning, residue tended to remain. Cleaning was required ten times daily, consuming 100 minutes of labour per day.

Consideration and Implementation of Countermeasures

■ Initial Countermeasure: Addressing via Mold Cleaning

Cleaning after each insert replacement suppressed defect leakage. However, this did not provide a fundamental solution and incurred significant time loss, necessitating a permanent countermeasure.

■ Consideration of Permanent Countermeasures

The following countermeasure proposals were compared and evaluated

Countermeasures | Effect prediction | Cost | Difficulty level | Expected effect |

Increase the thickness of the Y-rib | Improved liquidity | ○ | ○ | △ |

Additional gas vent | Gas escape assurance | △ | △ | ○ |

Gas relief pin installation | Gas emission from the tip | ○ | ○ | ◎ |

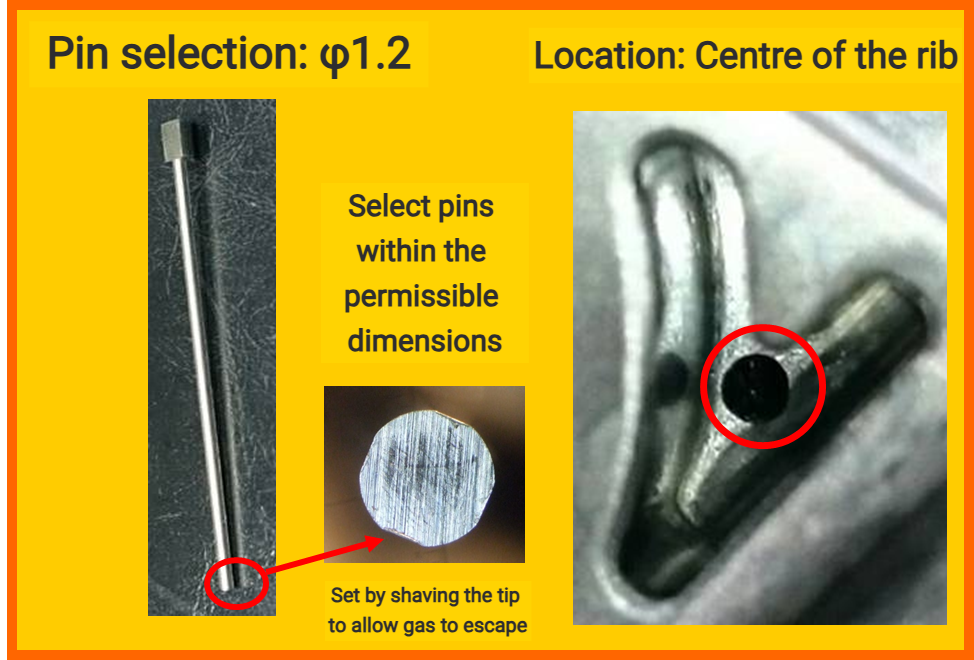

Ultimately, we selected the ‘installation of gas escape pins’, placing φ1.2 pins at the centre of the ribs and grinding their tips to enhance gas venting.

Results and Effects

Short circuit defects: Zero achieved

Following modification, 373,760 units were produced, recording zero Y-rib short circuit defects. Defects flowing into subsequent processes were also eliminated.

Significant reduction in cleaning man-hours: Mold cleaning frequency drastically reduced from 220 times per month to just once. This has lowered operational workload and reduced damage to the molds.

Improved mold condition: Even after two months post-improvement, mold interiors remain virtually free of contamination, enhancing maintainability.

Future Developments and Lessons Learned

For areas possessing features such as the Y-rib, which exhibit a “final filling position” and “dead-end shape”, gas escape pathways must be considered during the initial design stage.

Prototyping using transparent resin is effective for visually identifying the root causes of voids and strength defects.

For defects like those in this case, it is crucial to establish a system where T/E (Design) and the production floor collaborate closely, considering improvements from the perspective of mold structure.

Summary

For defects prone to recurring within processes, such as Y-rib short shots, permanent countermeasures rooted in mold, flow, and gas venting structures are required, rather than relying on symptomatic treatments. It is vital to accumulate insights towards achieving ‘zero defects’ at the molding site through initiatives like this case study and to extend these across the entire company.

![[Verification Experiment] Measurement of Gas Volume within Moulds Using the Water Displacement Method](https://static.wixstatic.com/media/217ce4_26c165f2dade4d15bf43c295c92471ed~mv2.png/v1/fill/w_747,h_599,al_c,q_90,enc_avif,quality_auto/217ce4_26c165f2dade4d15bf43c295c92471ed~mv2.png)

Comments