Glossary: what is shear heating?

- SANKO GOSEI

- Nov 27, 2024

- 2 min read

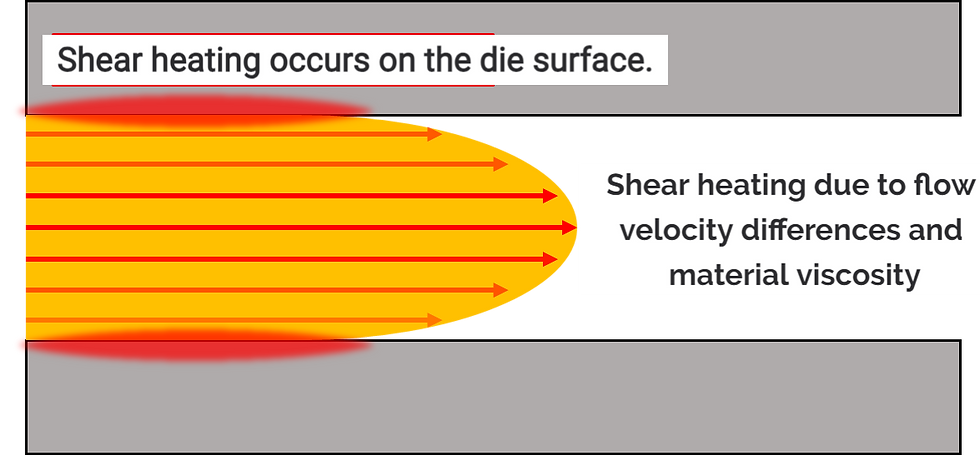

Shear heating is the frictional heat generated as the resin flows. In injection moulding machines, molten resin flows at high pressure through the screw and inside the mould. During this process, friction occurs as resin molecules rub against each other and between the resin and the mould surface, resulting in the generation of heat. This heat is called ‘shear heating’.

Shear heating is influenced by the following factors

Flow properties of resins (viscosity)

Higher viscosity results in increased shearing forces and higher heat generation.

Screw rotation speed and injection speed

The higher the speed, the stronger the shearing force and the more heat is generated.

Mould and runner design

If the flow path is narrow or complex, flow resistance increases and shear heating is intensified.

Impact of shear heating

Shear heating has a one-size-fits-all character. It is important to understand exactly what its effects are.

Advantages (moderate shear heating).

Resin is easily spread over complex shapes and details.

Short shots (phenomenon where resin fails to fill the entire mold) are prevented.

Smooth filling and improved surface quality of the molded product.

Disadvantages (excessive shear heating)

Thermal decomposition:

when the resin is exposed to high temperatures, the chemical structure breaks down, reducing the strength and durability of the molded product.

Gassing:

decomposed gases are drawn into the molded product, causing bubbles and a burnt smell.

Color change:

yellowing is particularly noticeable in white and transparent materials.

Key points for proper management of shear heat.

1. optimise injection conditions

Adjust the screw rotation speed and injection speed to reduce excessive shearing forces.

It is also important to avoid higher injection pressures than necessary.

2. resin selection

Resins with higher viscosity are more susceptible to shear heating, so it is important to select a material with the appropriate viscosity.

Resins with high heat resistance can reduce the risk of degradation due to temperature rise.

3. ingenuity in mold design

Design runners and gates to the appropriate shape and size to ensure smooth resin flow.

Shear heating can be controlled by considering the heat balance and maintaining a uniform mould temperature.

↑Device to reduce shear heating during flow by increasing the R of the runner.

4. thorough maintenance

Worn screws and molds can increase flow resistance and cause excessive shear heating. Prevent problems with regular maintenance.

Conclusion.

Shear heating is an unavoidable phenomenon in injection molding, but understanding its characteristics and managing it appropriately can improve molding stability and quality. Be aware of the fine balance between ‘not too hot and not too cold!’ The best molding conditions should be pursued with an awareness of the delicate balance between ‘too hot and too cold’.

Comments