What is ‘residual stress’ in injection molding? Can it be eliminated?

- SANKO GOSEI

- Aug 18, 2025

- 3 min read

One method of manufacturing plastic products is called ‘injection molding.’ Many plastic products around us, such as ballpoint pen caps, game console controllers, car parts, and lunch box lids, are made using this method.

However, injection molding is accompanied by a somewhat troublesome phenomenon called ‘residual stress.’ In this article, we will explain what residual stress is and whether it can be eliminated, using examples.

What is residual stress?

First, let's look at the meaning of the term.

‘Residual’ = remaining ‘Stress’ = force exerted on an object

In other words, ‘residual stress’ refers to a state where an invisible force remains within an object.

For example, when pouring jelly or chocolate into a mold and cooling it, the outer layer cools and solidifies first, while the inner layer solidifies later. At this point, the outer layer tries to contract quickly, but the inner layer resists contraction, as if saying, ‘It's still hot!’

In this way, when the cooling and shrinkage rates differ between the outside and inside, forces are generated within the material that pull and push against each other. These forces remain inside even after cooling—this is residual stress.

It also occurs in plastics!

In injection molding, plastic is melted at high temperatures, poured into a mold, cooled and solidified to create a product. However, just like jelly or chocolate, the outer and inner parts of plastic cool at different rates.

As a result,

the outer part cools quickly and tries to shrink,

while the inner part is still hot and does not shrink.

This causes a conflict between the ‘force trying to shrink’ and the ‘force resisting shrinkage’ within the material, leading to the accumulation of force inside.

Additionally, when plastic is forced into a mold, the molecular orientation becomes disordered, and the material may solidify with an imbalance of forces. This also causes residual stress.

What happens when there is residual stress?

When there is residual stress, invisible forces such as ‘pulling forces’ and ‘pushing forces’ are at work inside the product. This can cause the following problems.

💥 Increased susceptibility to cracking → Cracks may suddenly appear even without applied force.

🌀 Warping or deformation → A plate that was flat immediately after molding may warp over time.

🛠 Difficult to process → After cutting or welding, the shape may shift or deform again.

Is it possible to eliminate residual stress?

Unfortunately, it is almost impossible to completely eliminate residual stress. This is because all materials shrink when they cool down. When the degree of shrinkage varies depending on the location, stress is generated.

However, there are ways to minimise it!

Ways to reduce residual stress

① Cool slowly

Rapid cooling causes a large temperature difference between the outer and inner layers, making it easier for stress to occur.

➡ By increasing the mold temperature or extending the cooling time, you can achieve balanced cooling.

In other words, arbitrarily lowering the mold temperature to shorten the molding cycle can cause stress on the material

molding process.

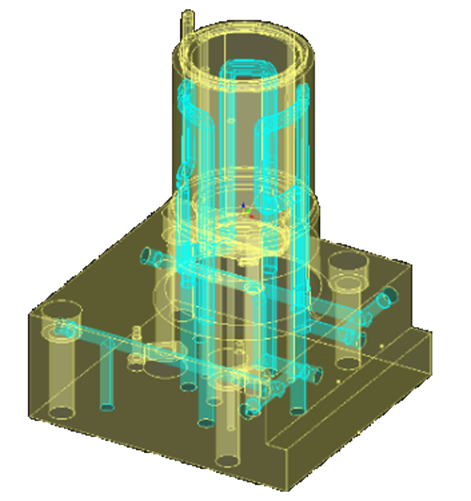

② Maintain uniform mold temperature

Inconsistencies in the flow and cooling processes can lead to stress. Especially in deep shapes, there is a tendency for temperature differences in the mold to become significant.

➡ Uniformity can be achieved by optimising the mold's cooling water piping and gate positions.

③ Optimise moulding conditions

By adjusting the injection pressure and injection speed to ensure uniform plastic flow (flow length), molecular orientation and distortion can be suppressed.

➡Flow length control using a valve gate

④ Performing annealing treatment

This involves reheating the molded part to relax the molecules. However, depending on cost and shape, this may not always be feasible. For more information on annealing treatment, see ➡here

Summary: Managing residual stress effectively

Residual stress in injection molding is an unavoidable issue in manufacturing. While it may not be possible to completely eliminate it, it is crucial to minimise it to prevent problems.

The plastic products we use without a second thought. Their invisible inner workings are filled with wisdom, such as material properties, cooling techniques, and molding technology.

That is why understanding residual stress and making efforts to reduce it leads to better product manufacturing.

If a product suddenly breaks or becomes distorted, you may realise, ‘Oh, it might be due to residual stress.’

Comments