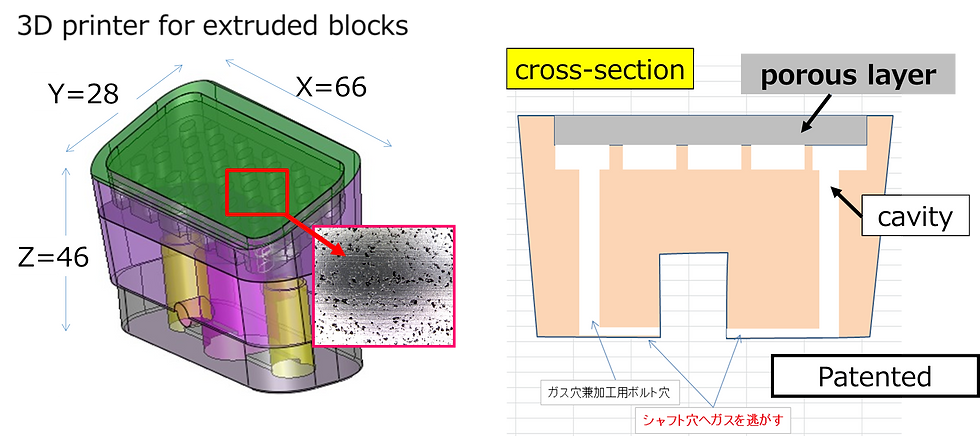

3D printer Gas venting nesting device Application example in ejector block

- SANKO GOSEI

- Feb 9, 2023

- 1 min read

Updated: Feb 10, 2023

Gas bubbles and white smoke around the protruding block during mass production of automotive parts

The failure rate was 10%, and mold maintenance was performed every 3,000 shots.

Although commercially available gas venting inserts had gas permeability, they were prone to clogging and required mold maintenance as well.

We therefore designed and fabricated a unique ejector block with gas permeability and no clogging using a 3D printer.

The 4mm surface layer of the block is a porous structure with a cavity just below it.

After the introduction of the 3D printer ejector block, the defect rate was reduced from 10% to 0%.

The estimated cost of the ejector block modeling this time was 300,000 yen, which is more than enough cost-effectiveness considering the reduction of maintenance and the improvement of defect rate.

As for the production period, if you place an order after designing the new model, it will be ready in time for the mold completion.

If you are in a hurry, please contact us.

For inquiries, please contact

Mizuno & Hayashi, Sales Group, T&E Business Unit, Sanko Gosei Co.

TEL0763-62-3899 sg.wind@sankogosei.co.jp

Comments