In-mould punching and forming technology (1)

- SANKO GOSEI

- Jan 18, 2023

- 1 min read

However, depending on the shape of the product and the resin flow, weld lines may appear where they are not wanted.

However, there are cases where weld lines may appear in places where they are not desired, depending on the product shape and resin flow.

Weld lines can be made less noticeable, but they cannot be completely eliminated.

As a desperate measure to completely eliminate weld lines, our company uses the following methods.

We have achieved weldless moulding with holes by moulding and punching the resin in the mould at the same time.

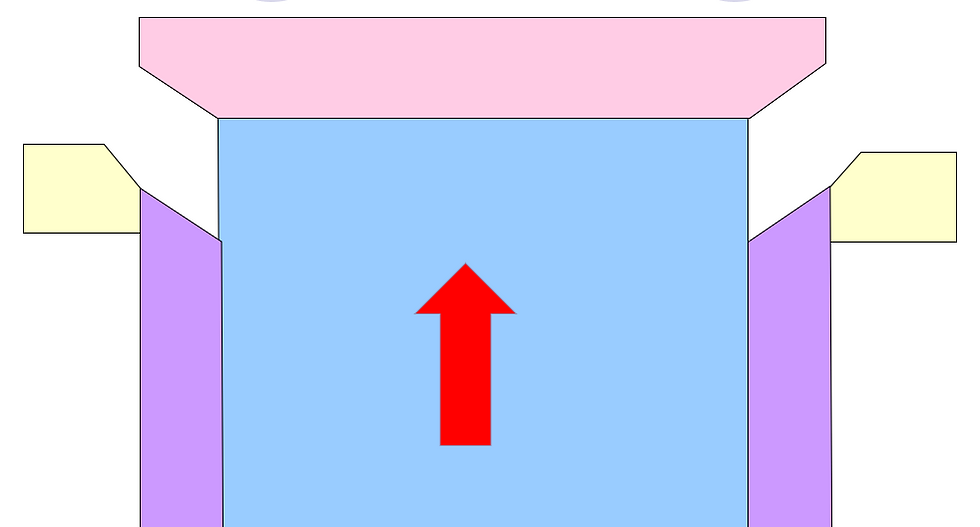

・In-die punching mechanism

(1) Form the tabs together (the tabs are made thinner to facilitate punching).

(2) Advance the sleeve pin to separate the product from the tab.

(3 Center pin to push out the separated tabs.

The above is the punching mechanism.

In this case, the timing at which the sleeve pin is moved forward and the tabs are separated in (2) is important.

If the timing is too early

The resin goes around the punching pin, causing welding together with the hole shape.

When timing is slow

The resin cools and solidifies, making it impossible to separate the tabs.

We have drawn up a condition control chart and thoroughly eliminated punching defects.

Comments